Electric Overhead Travelling (EOT) Cranes

LIFTBOY Electric Overhead Travelling Cranes are designed and manufactured in accordance with IS:807, IS:3177 code of practice for design and manufacturing, erection & testing of structural portion of crane and IS:3177 code of practice for design of overhead cranes.

Our cranes are designed considering adequate factor of safety with respect to appropriate duty classification.

Our product range includes Single Girder EOT/HOT Cranes, Double Girder EOT/HOT Cranes, and Under Slung Cranes.

LIFTBOY Cranes are available in wide range of capacities starting from 1 ton, up to 100 ton.

Following are the major features of this range:

Highly reliable

Efficient in operations

Easy operation

STRUCTURAL

Main Girder

Standard, ISMB, Lattice girder or Plate Box Girder Section, well designed and fabricated as per IS:807 and IS:3177 and fabricated out of IS:2062 Freely Weldable Quality Material.

End Carriage

Fabricated out of standard steel sections or plates to support the main girder at both the ends. The end carriage are fitted with double flanged crane wheel mounting with L Block housing or suitable open red, made of high quality steel casting or forged steel, running on ball/roller bearings.

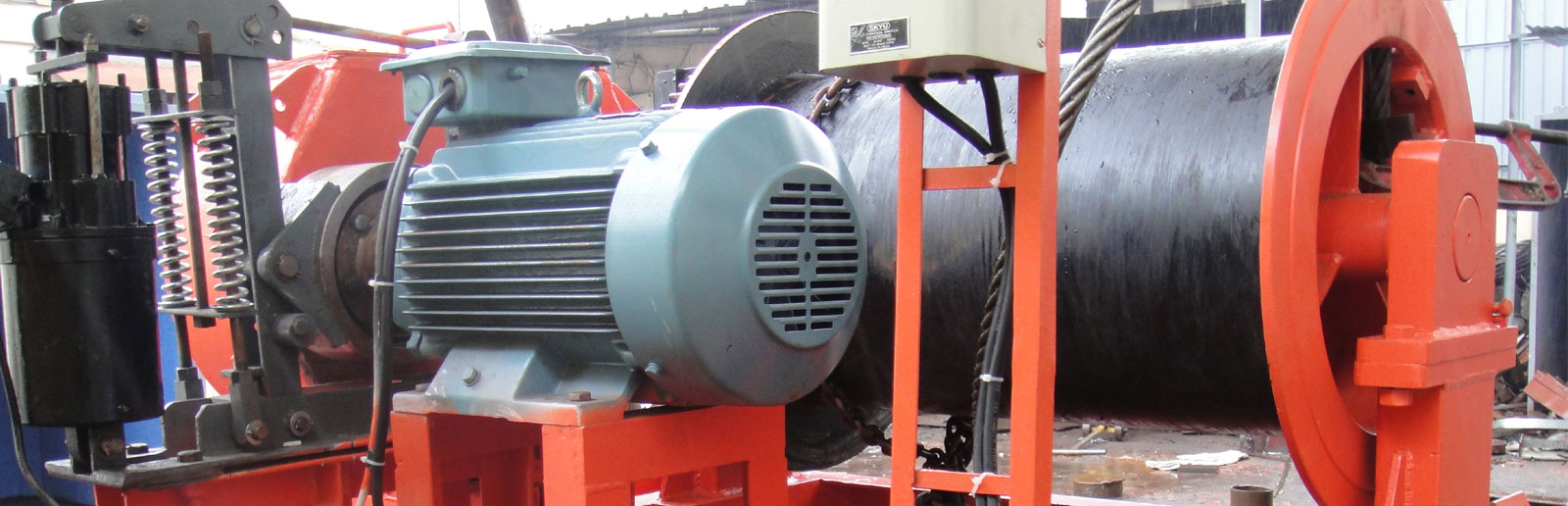

MECHANICAL

Gearboxes & Couplings

Graded C.I./Fabricated Gearbox housing are machined to close tolerance (± 0.02 on center distance, 0.01 deviations on bore form & H7/H6 bore tolerance. Gears and pinions from forged C55/40Ni2Cr1Mo28 are precision hobbed for correct involute profile. Bearings (ball and roller) from manufacturers authorized stockists) support pinion & O/P shaft are assembled by highly skilled technicians who have been building machine tools with us for over years. O/P shaft for main/auxiliary hoist gearboxes are forged integral with single crown coupling resulting in almost maintenance free hoisting unit. CT & LT gearboxes with single/double hub coupling from C45 are precision cut form and with minimum clearance, yet taking care of angular, axial misalignment during assembly. Aligning I/P, O/P gearboxes shafts with motors, drum or floating shafts is done with care as if these are rigidly connected.

Wheels

Crane wheels forged, machine true (tread diameters held true to ±0.1) on precision machines are subsequently hardened and tempered to 250-300 BHN to give a long life to travelling machines. Wheel axels are ground to hold very close tolerance at bearing ends, wheel zones and coupling hub connection. This helps in easy changeover of wheels during maintains as interchangeability is guaranteed during manufacturing.

Rope & Hook

Rope to IS:2266 with minimum factor of safety 6 & hooks proof load tasted to IS:8610/IS:3815 are bought and certified.

ELECTRICAL

Motor

Crane Duty, three phase, 415 Volt, 50 Hz. AC Squirrel Case Induction Motor with high starting torque and TEFC continuously rated. Motors are suitable for frequent reversing and are of standard makes like Crompton, Bharat Bijlee, NGEF etc. Slip-ring motors are also available on special applications.•

Brakes

AC Electromagnetic Shoe/Disc Brakes are used for compactness and instantaneous braking characteristics. Hoisting brakes are selected with minimum 150% of running torque as per IS:3177 & IS:3198. Electro-hydraulic Thruster Brakes are also used on special applications.

Control Panel

Dust Proof, well designed control panels, fitted with switch gears, fuses and step-down transformers etc. are used. Push Button Pendent, Station Operating Line Contactors, Press-to-run Button for each direction of motion with Direction Legends are used. Safety Limit Switches are provided for stopping the lifting operation and lowering motion at the extreme position of the hook block.

HOT Cranes

We are well known manufacturers of high quality of HOT Cranes. These cranes are made in accordance with 1SS: 226 I or 1SS: 2062 standards ensuring high resistant to vibrations. These state of art cranes are durable, robust and reliable. Since these are made out of class A raw materials like crane and hoist duty motors and other electrical components, therefore, these cranes function flawlessly. We lay special stress on design of the cranes to be such that they are easy to use and user friendly. Our overhead HIT cranes are highly in demand in local as well as overseas market due to factors like these have 100% radiography welded joints. The cranes have high quality brakes, and are very resistant to rust.

Features:

Corrosion resistance

Durability

High strength

These are used in following areas:

Construction industry

Shipping yards

Road sides

Mines

Quarries

Heavy fabrication unit

Contracting firms

Factories

Power stations

Large water works

Railway yards

Harbors

Water houses

Transporters

Single/ Double Girder EOT Cranes

With vast experience and knowledge we are engaged in offering a comprehensive range of Bridge Cranes , Double Girder Bridge Cranes & Single Girder Bridge Cranes from 1 Ton to 20 Tons. These handle the load in an efficient manner and have a bridge with end trucks. Our products are developed using high grade material which is procured using from reliable vendors of the market. In addition to this, these are highly appreciated among our clients due to their superior finish, resistant to corrosion and competitive prices.

Underslung Cranes

We have carved a niche for ourselves in the industry by offering Under Slung Crane, which are manufactured without any technical error. Leveraging on our highly equipped fabrication capabilities, we have developed our expertise in offering a customized range of:

Under Slung Overhead Cranes

Under Hung Overhead Cranes

Suspension Type Single Girder Overhead Cranes

These are used as a material handling equipment in host of industries.

Gantry Cranes

We are leading manufacturers of self propelled Gantry Cranes. These run on rails installed at ground level. We manufacture both the Single Girder type and Double Girder type of gantry cranes. We can also customize these cranes according to your specific requirements. Our cranes are largely used in construction works, Ports and harbors, small and compact workshops, worksites with changing or large bay lengths. These cranes are easily movable and especially useful where only part utilization of workshops has to be done.

Features:

Highly efficient

Durable

Robust

Goaliath Cranes

We are leading manufacturers of self propelled Goliath Cranes. These run on rails installed at ground level. We manufacture both the Single Girder type and Double Girder type of gantry cranes. We can also customize these cranes according to your specific requirements. Our cranes are largely used in construction works, Ports and harbors, small and compact workshops, worksites with changing or large bay lengths. These cranes are easily movable and especially useful where only part utilization of workshops has to be done. These cranes are highly efficient, durable and robust.

Features:

Low maintenance cost

Hassle-free operations

Durable

JIB Cranes

Liftboy Industries are well versed in fabrication of high quality of JIB Cranes. Our cranes are widely in use for material and machinery loading, small assembly jobs, localized fitting etc. Their superior design allow them to use minimum floor area and are lighter in weight. Our Jib cranes are easily rotated from angles ranging from 180 degrees to 360 degrees. The Jib Cranes are easy to install and use. The Cantilever type boom allows maximum hoist lift. These cranes have a capacity of 0.5 Ton to 20 Ton.

Features:

Light weight

Durable

Reduces labor cost

Easy handling

Less time consuming

Multifunctional within Work Area